CREATIVE PROCESS: UNDER ARMOUR SS19

BRIEF:

I was hired by Under Armour in January 2018 to design a limited-edition fashion active capsule for their new launch line UAS, Under Armour Sportswear. The goal was to test the market/consumer’s interest in a more fashion-directed sportswear line.

This was to be a speed-to-market collection with a fashion/lifestyle approach, positioned to align with NikeLab, Adidas Originals and KITH. It needed to be recognizably Under Armour, yet differentiated from the main line.

The capsule would be a 2-delivery group of womens and mens fashion active/lifestyle sportswear for the established, performance-led brand.

CONCEPT:

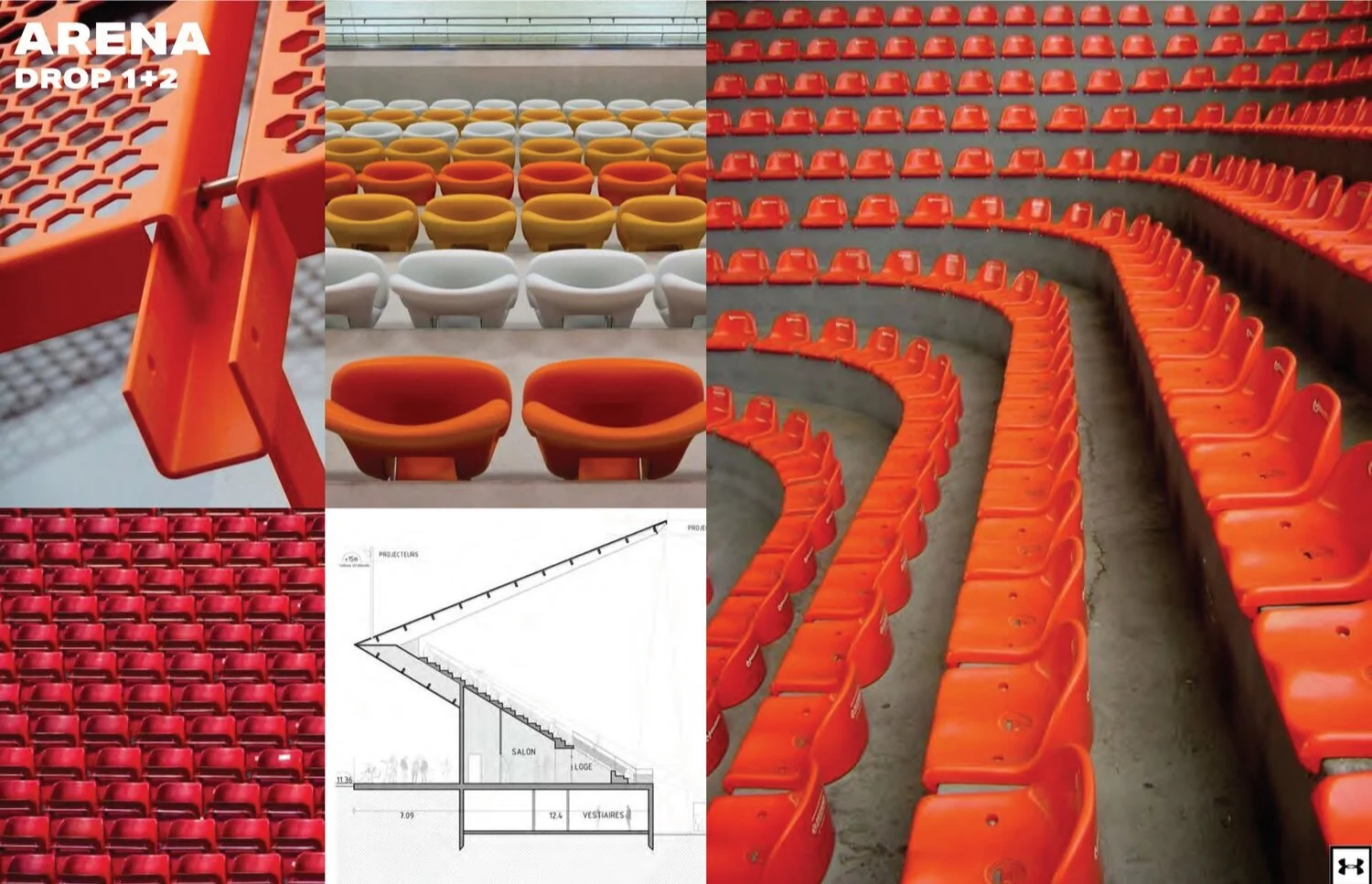

For this special project with Under Armour, I kicked off the design process with in-depth development of a single, overarching concept: Arena.

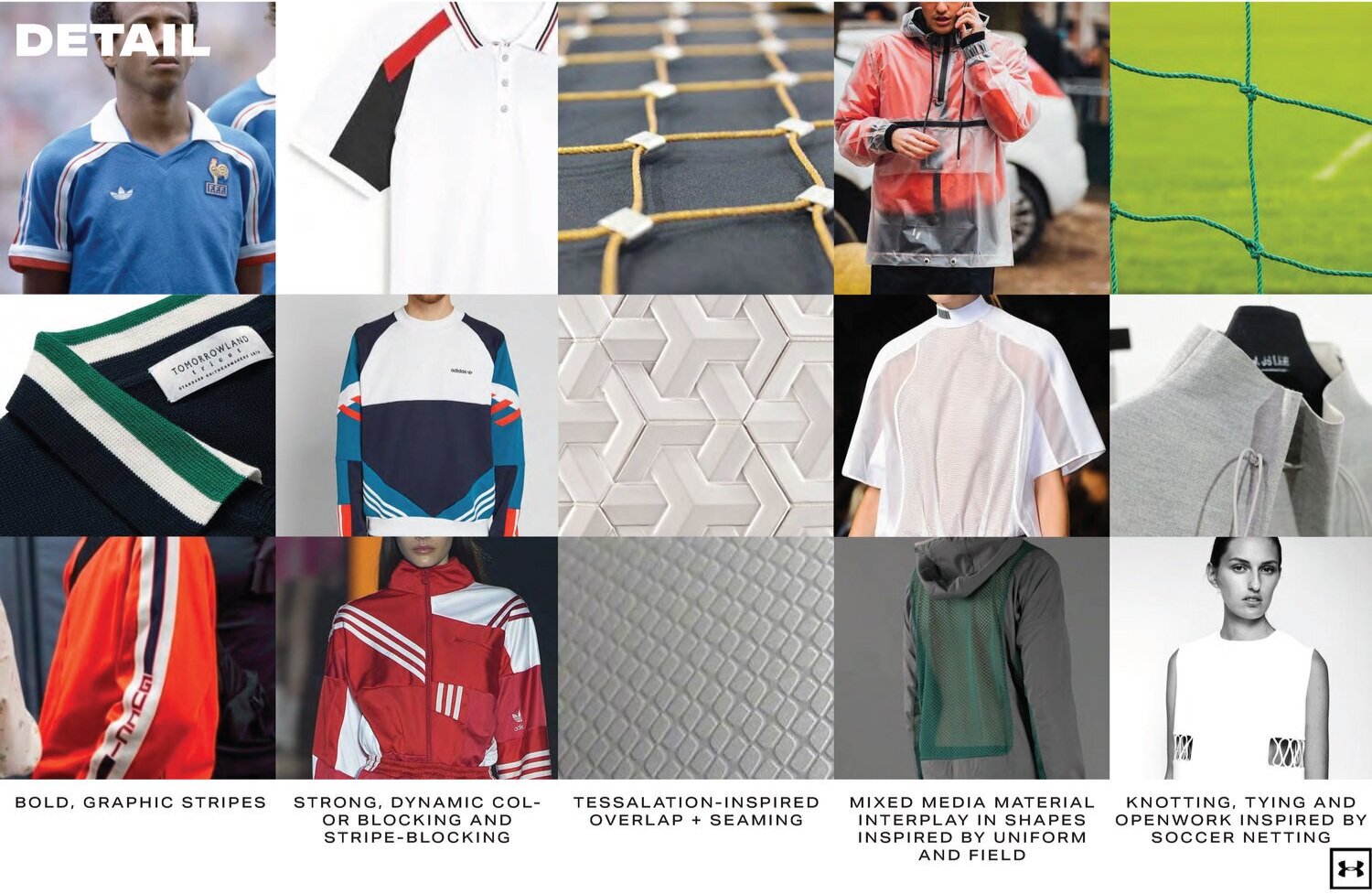

The Arena epitomizes the idea of on-pitch/off-pitch lifestyle; combining the tribal energy of stadium sports, the bold graphics of team differentiation and a nostalgic sense of 90s footballer swag.

Building on a soccer influence in Drop 1+2, drop 3 evolved into another growing stadium sport: racing. Utilizing many common graphic details, performative needs, and a shared 90s popularity, I was able to create a smooth bridge between drops and tell a larger Arena story.

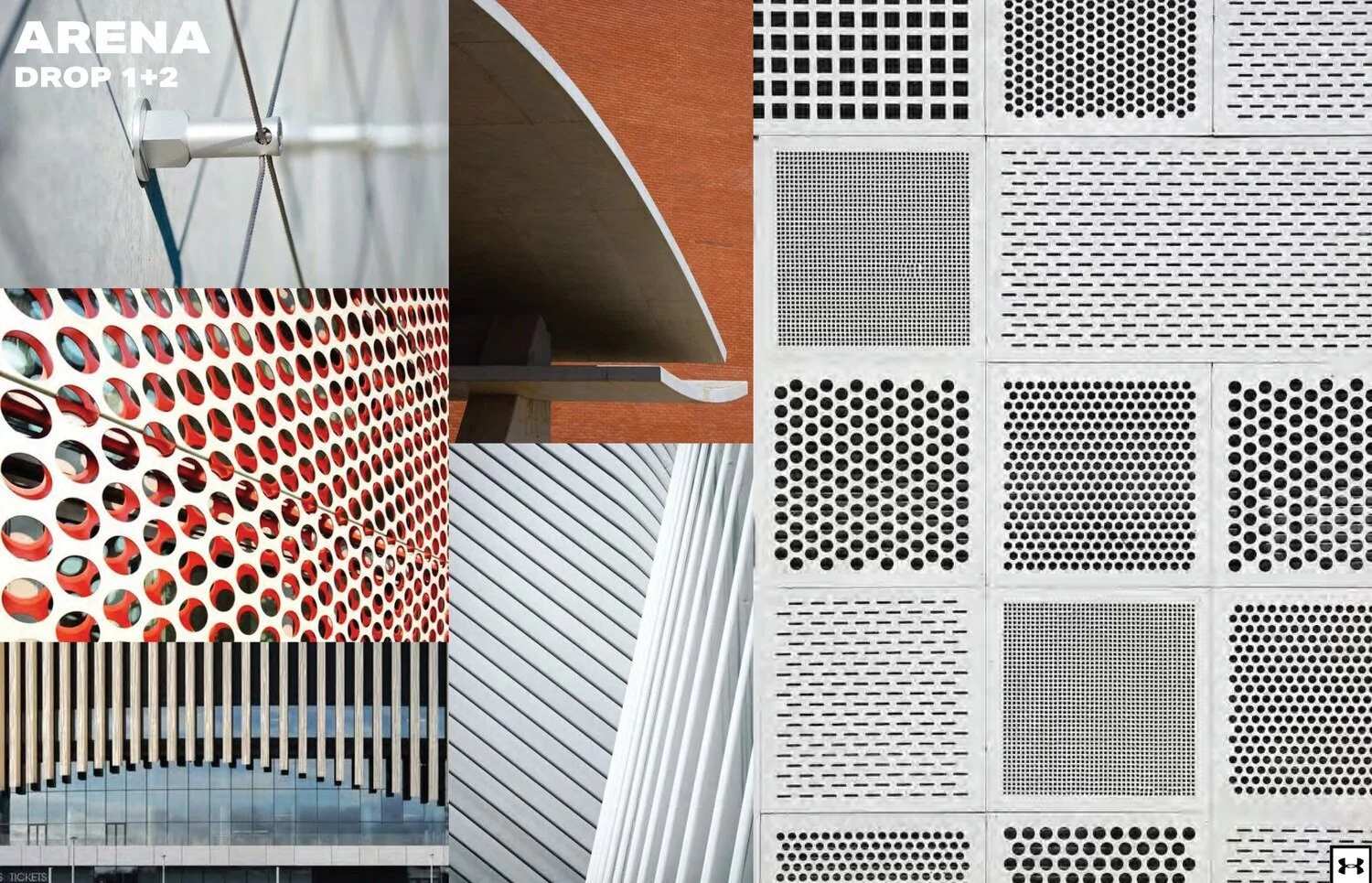

Diving deeply into my concept, I explored all physical aspects of a stadium/arena experience.

The open-air architecture with its contrast of mass/void, the geometric lines of field markings, the bold color and ergonomic curvature of stadium seats, and fine knotting/mesh textures of nets and ventilating external building materials.

MATERIAL TOOLKIT DEVELOPMENT:

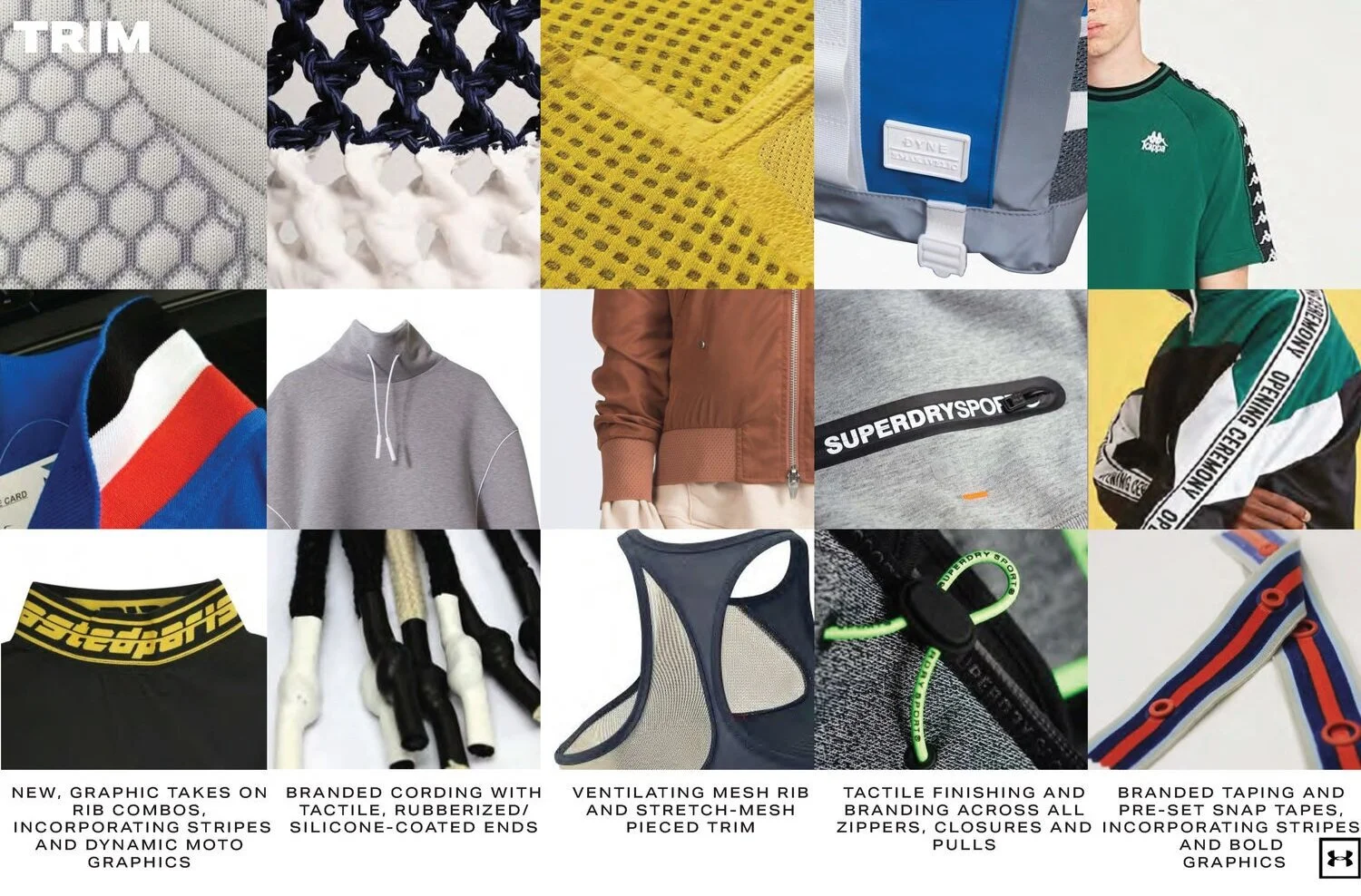

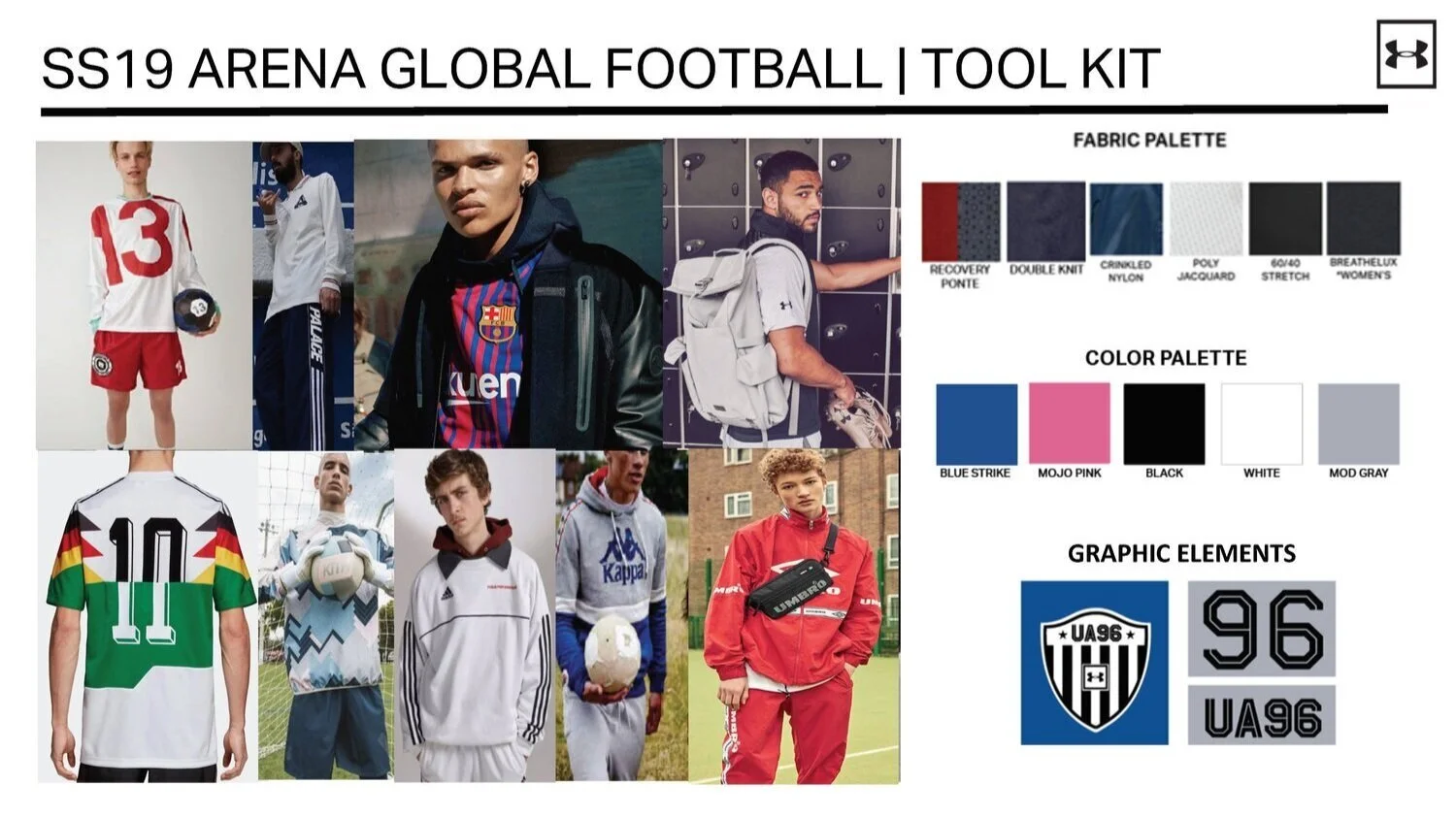

After exploring all aspects of the concept, I went to work extrapolating inspiration points for materials, trim, graphics and details.

I found endless material inspiration in innovative stadium architecture and the way these stadiums are designed to mitigate overwhelming crowd warmth, noise and weight.

TRIM DESIGN DIRECTION:

Trim was inspired by soccer netting and the tactile experience of being in a stadium, sitting it its smooth plastic seats, in the open air.

GRAPHIC DESIGN DIRECTION:

Graphic design drew inspiration from vintage World Cup posters, x-racing sponsorship branding, and 3D branding application methods.

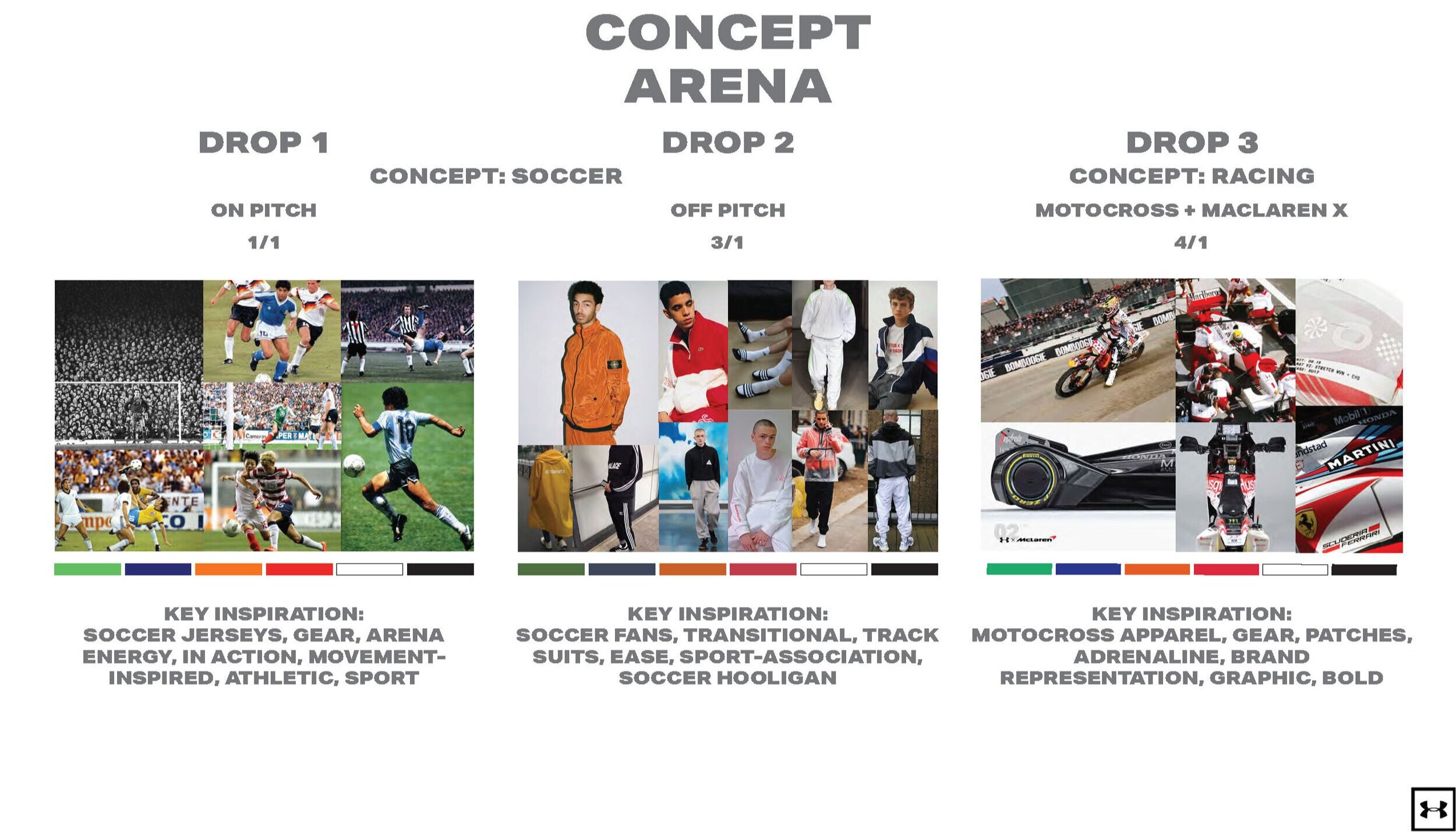

MOOD BY DELIVERY:

Originally slated to be released over 3 drops, I differentiated the deliveries into 3 sub-concepts:

On-pitch (Training), Off-Pitch (Recovery), and Next Gen (X-Racing inspired).

Drops 1+2 were later combined for a March 2019 delivery, with Drop 2 delivering in May 2019.

MARKET RESEARCH:

Drop 3 required a Graphic Design refresh, to differentiate the product on the floor pad and in campaign imagery. Drop 3’s graphics were inspired by 80s VHS tape product design, branded BMX racing gear.

SKETCHING:

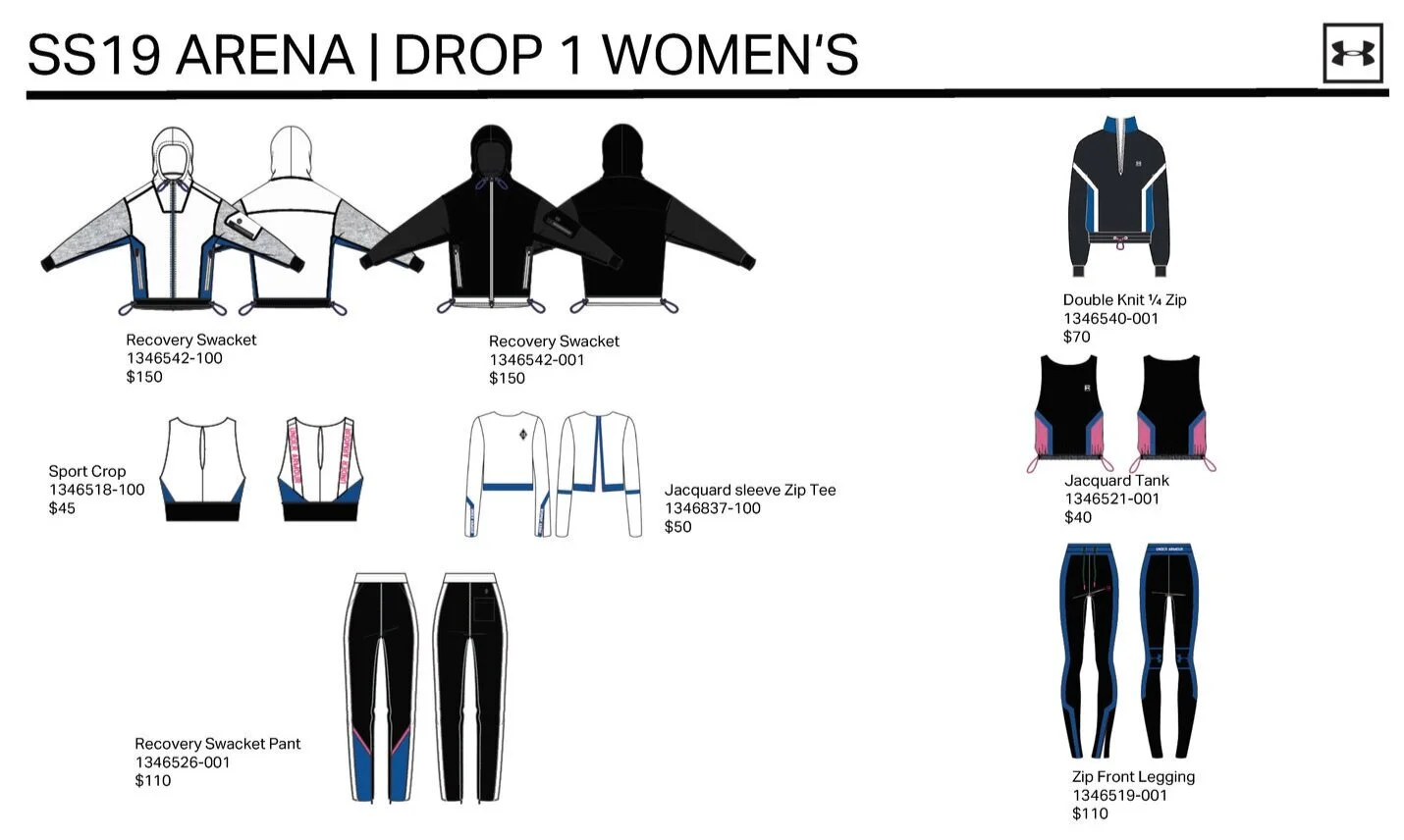

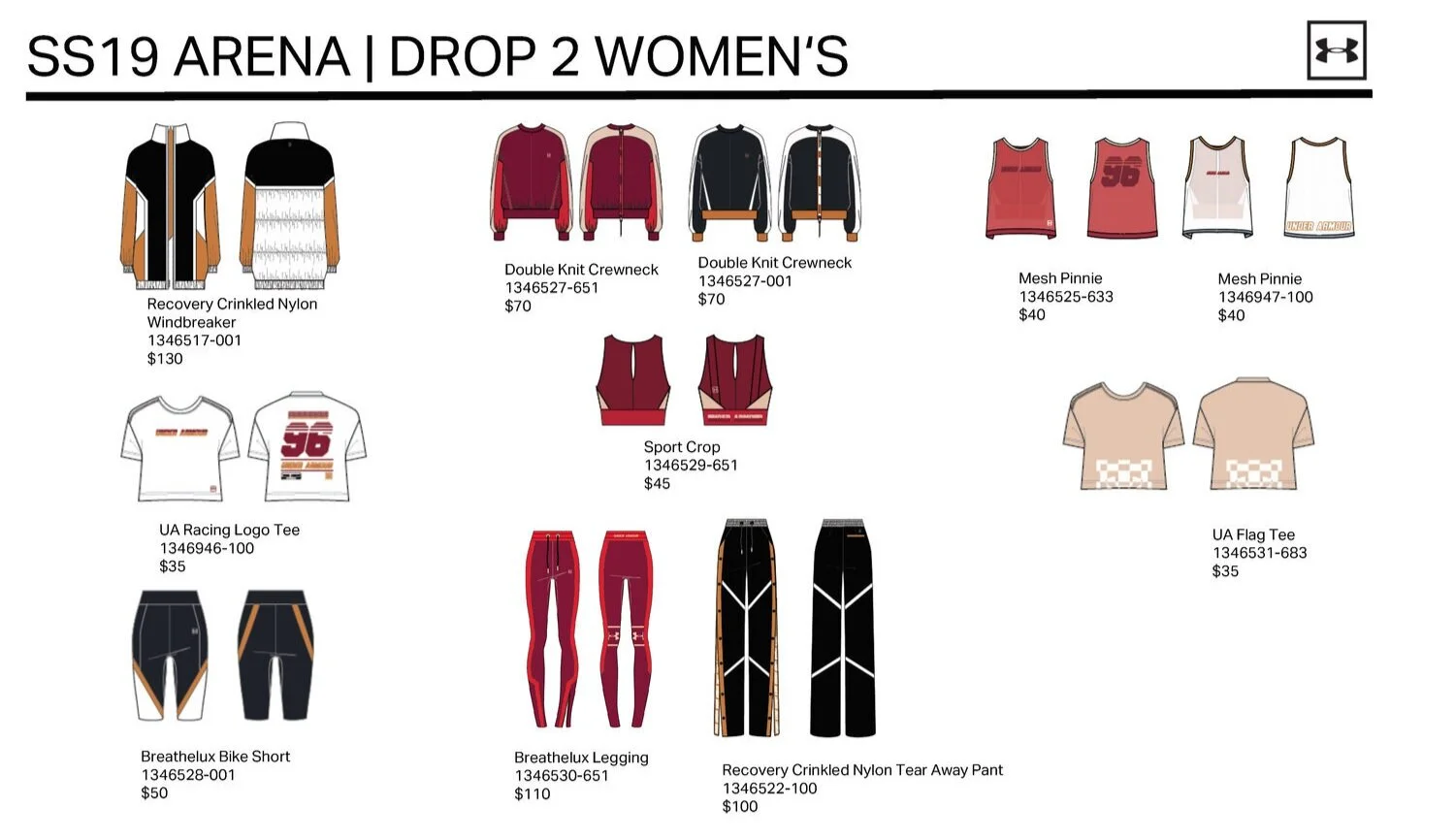

With the concepts presented and aligned on with Under Armour leadership, I dove into hand sketching.

I sketched at a 3:1 ratio, handsketching about 125 sketches in 1 wk with a goal of 39 styles for line adoption. As this was a speed-to-market collection, we had under 2 months from concept to handoff, with constant leadership alignment check ins and inclusive of all fabric sourcing and development.

TOOLKIT + KEY IDEAS:

After visiting the Fabric Archive at UA HQ in Baltimore, I selected a mixture of Under Armour’s nostalgic materials like crinkled nylon and their patented Recovery material to stimulate physical regeneration during downtime/post-exercise.

DESIGN DEVELOPMENT + TECH PACKS:

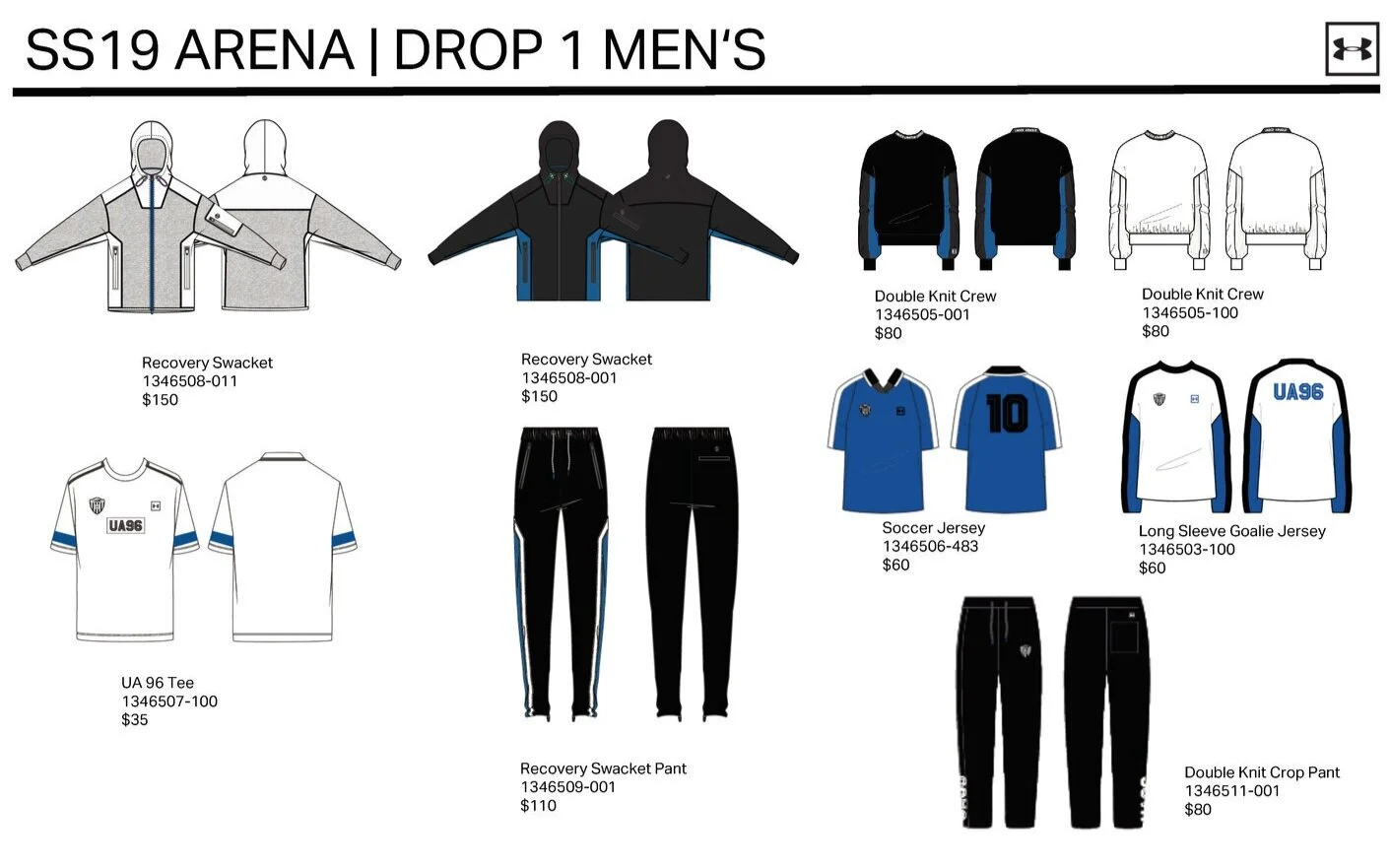

With handsketches reviewed by Merchandising, I CAD’d a 2:1 development ratio of selects and proceeded into tech pack development.

Working closely with UAS’ Graphic Designer and Trim Designers, I executed custom graphic and trim elements that would be ready alongside material in time for the factories to begin proto development.

3D FIRST PROTOS:

UAS began exploring 3Ds as a first proto process, to alleviate incorrect design line placements and constructions on first samples and shave 1 month off development process.

2ND PROTO FITTINGS:

After providing 3D proto fit and design comments, we fit physical 2nd protos from our manufacturing partners in correct materials, graphic elements, and trim. I fit each sample alongside Tech Design, working to ensure fit follows a combination of my design intent and the brand’s standard fit so it is brand-right, while differentiated.

FINAL PRODUCT:

Finally, the product was refit after 2nd proto fittings, and photo samples were made.

The campaign was shot on Australian fitness influencer and model Steph Claire Smith.